В условиях цифровой трансформации промышленности эффективное управление активами становится не просто инструментом оптимизации, а стратегическим фактором устойчивого развития бизнеса. Предприятия используют всё более сложное, дорогостоящее и высоконагруженное оборудование, а требования к производительности, безопасности и прозрачности процессов постоянно растут. Именно поэтому системы управления активами (Enterprise Asset Management, EAM) сегодня занимают ключевое место в операционной деятельности промышленных компаний.

Грамотно выстроенное управление активами позволяет обеспечить бесперебойную работу оборудования, повысить эффективность производственных процессов, снизить операционные затраты и увеличить общую прибыль предприятия.

Что такое система управления активами на основе трекинга?

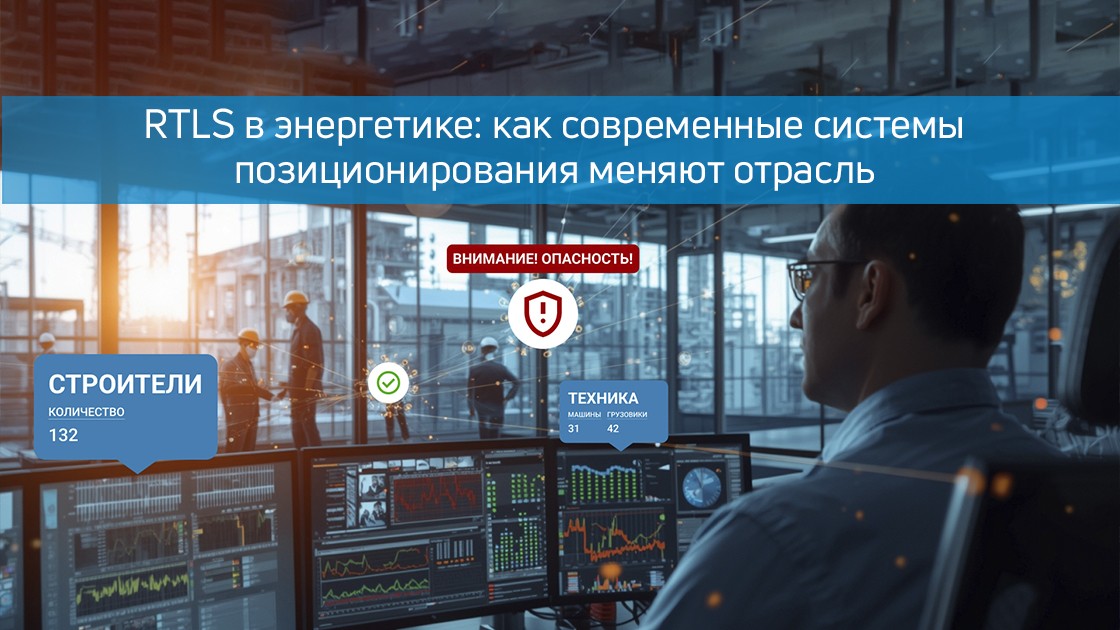

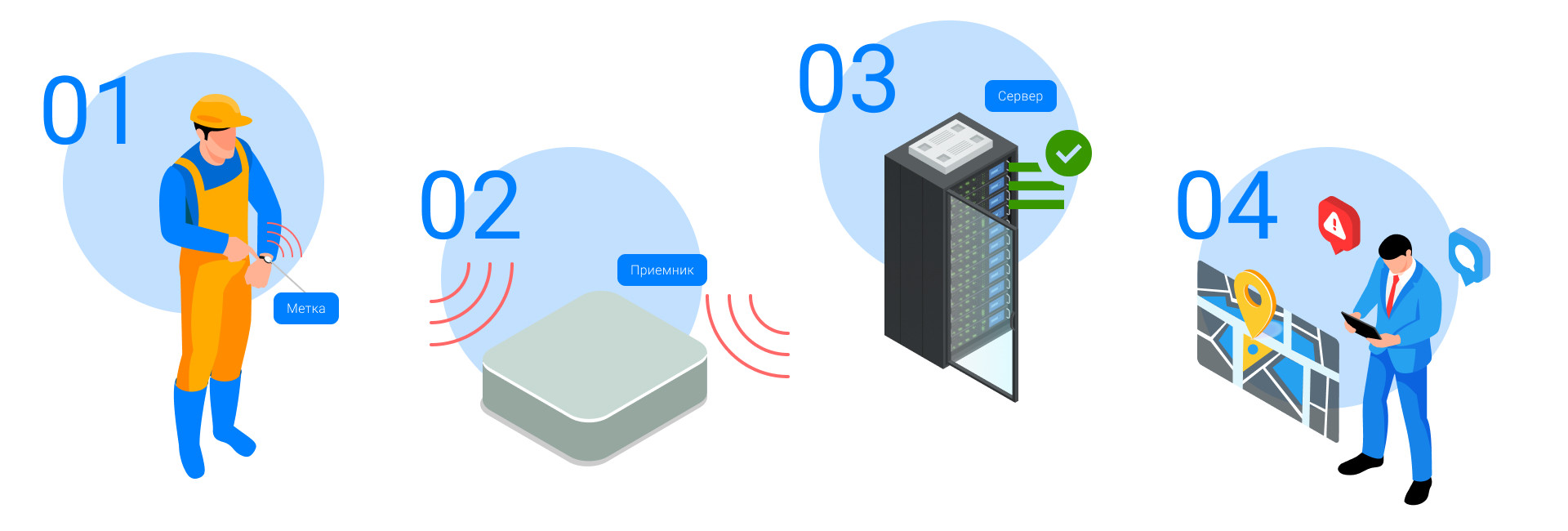

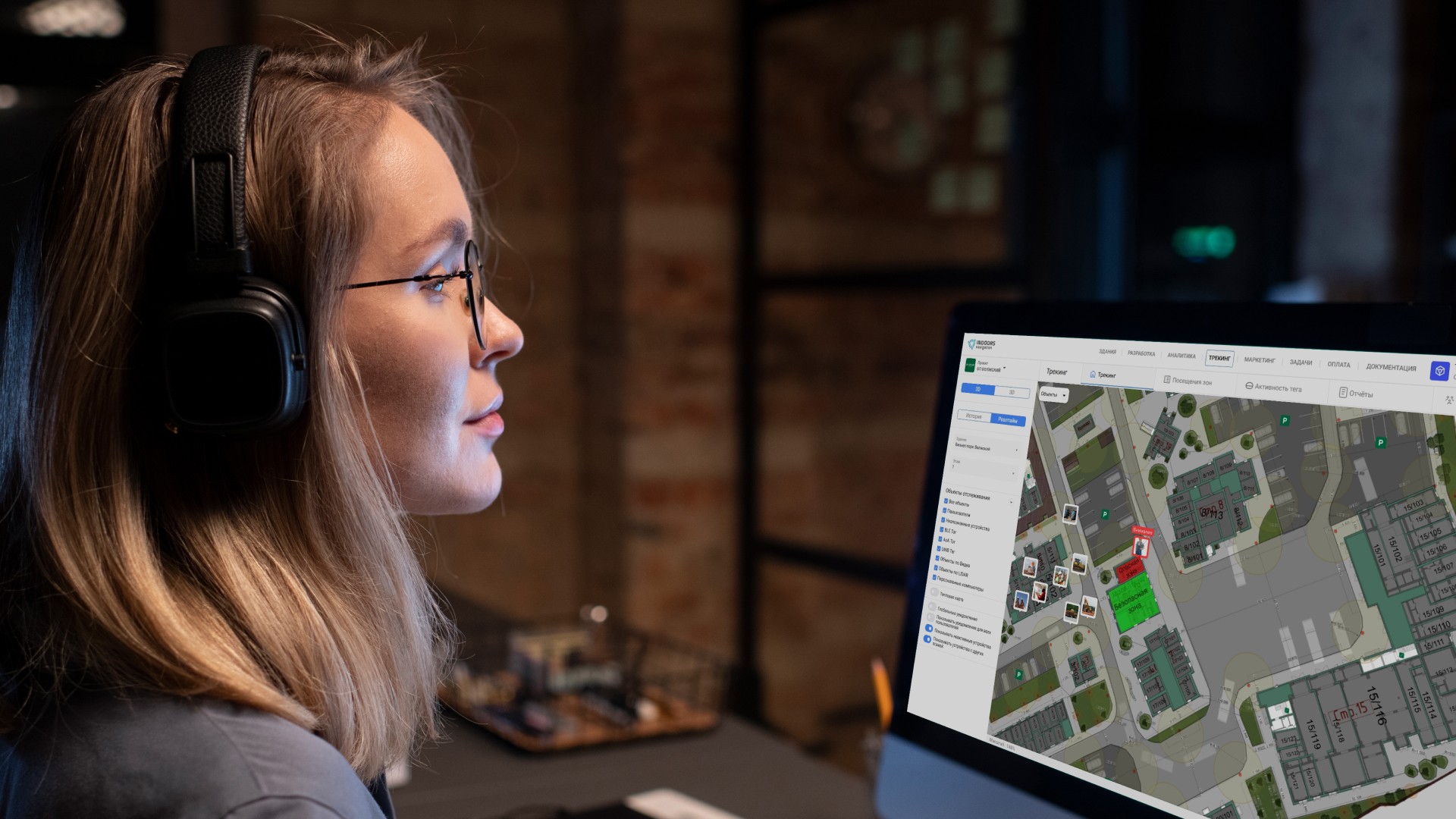

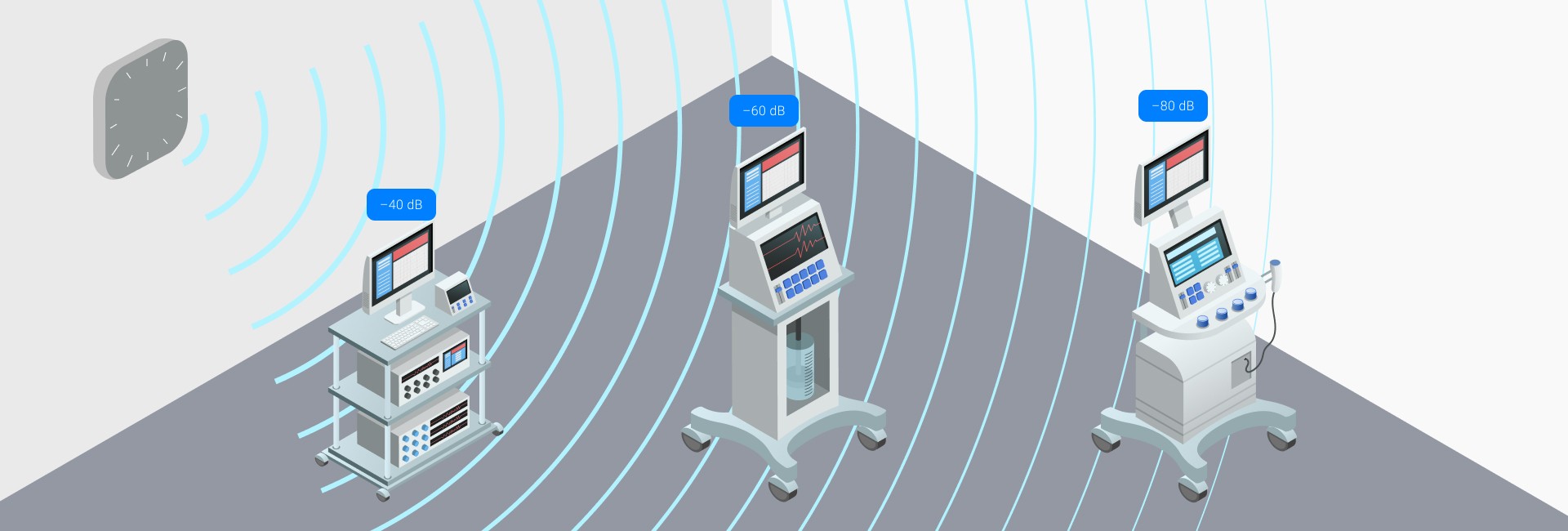

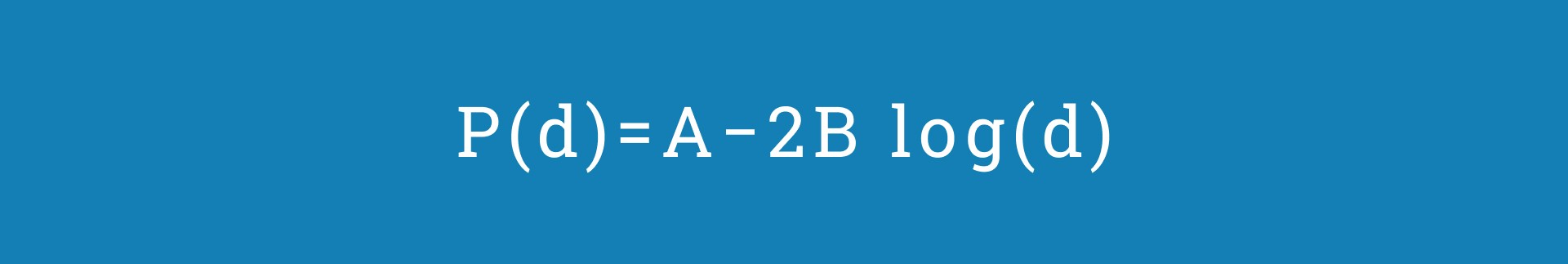

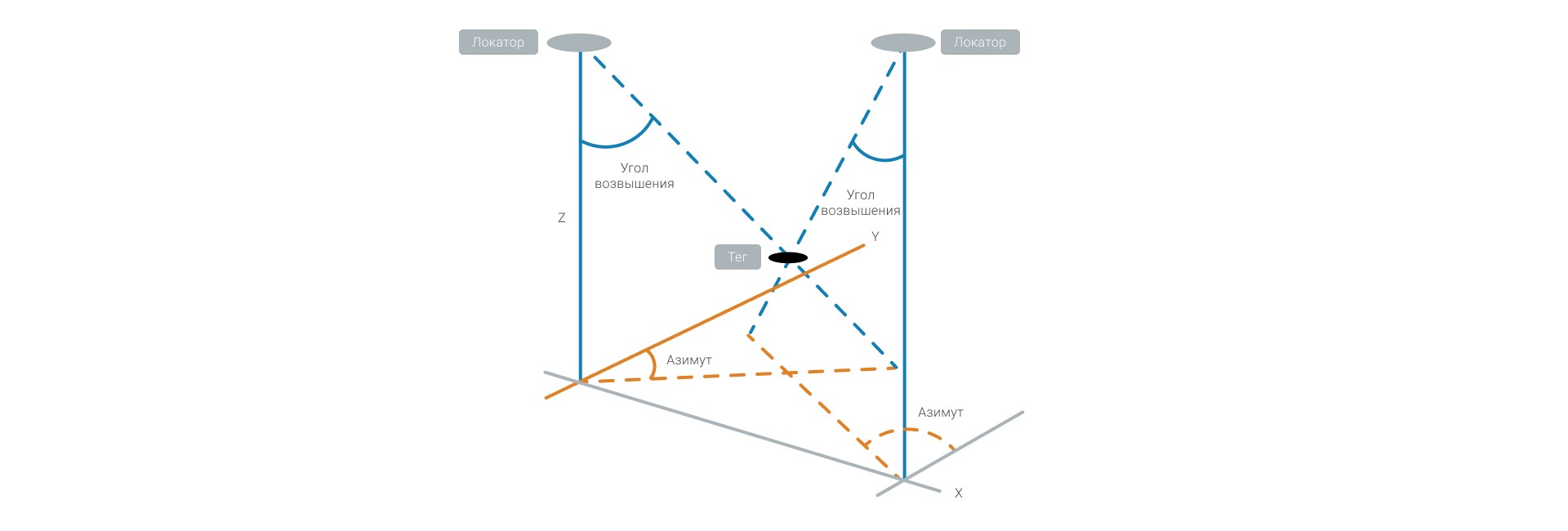

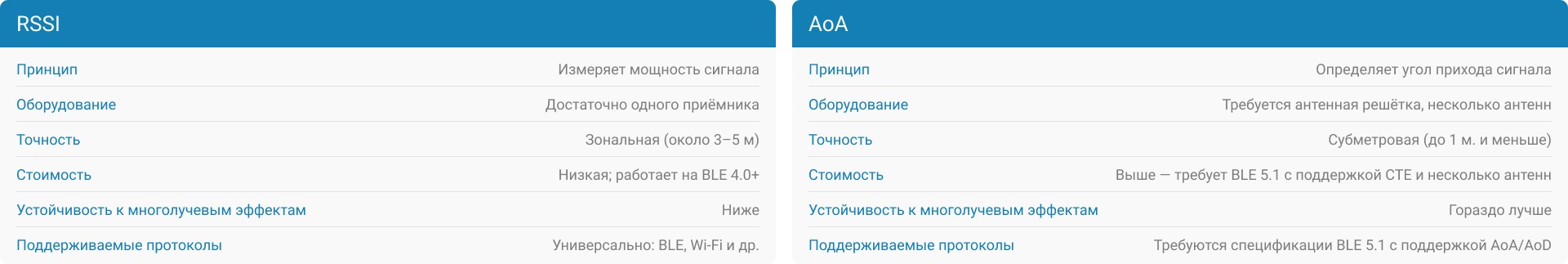

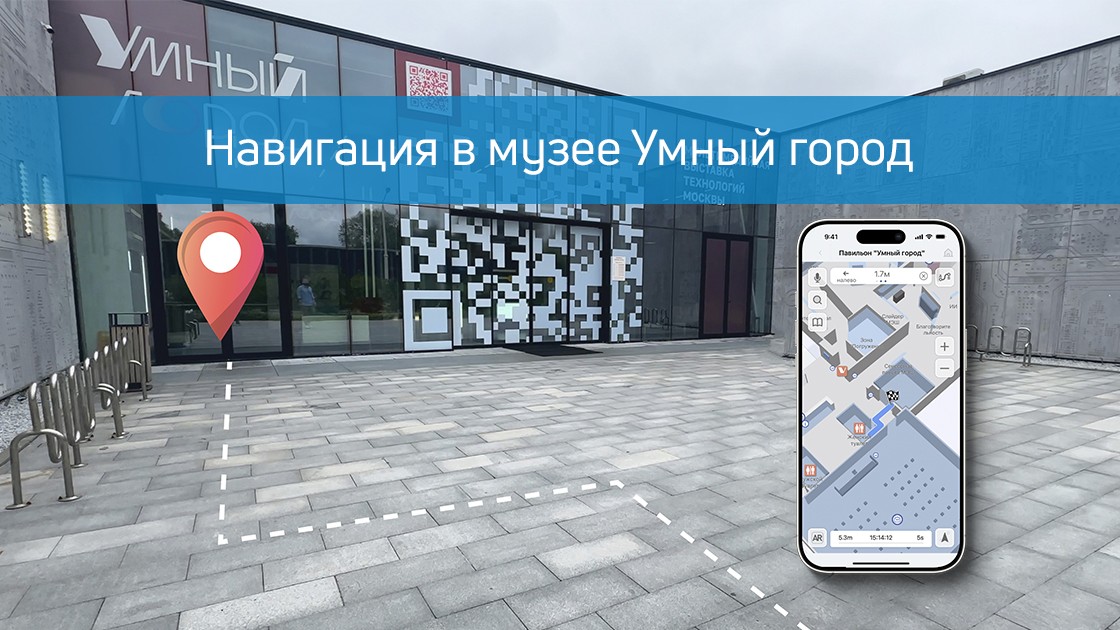

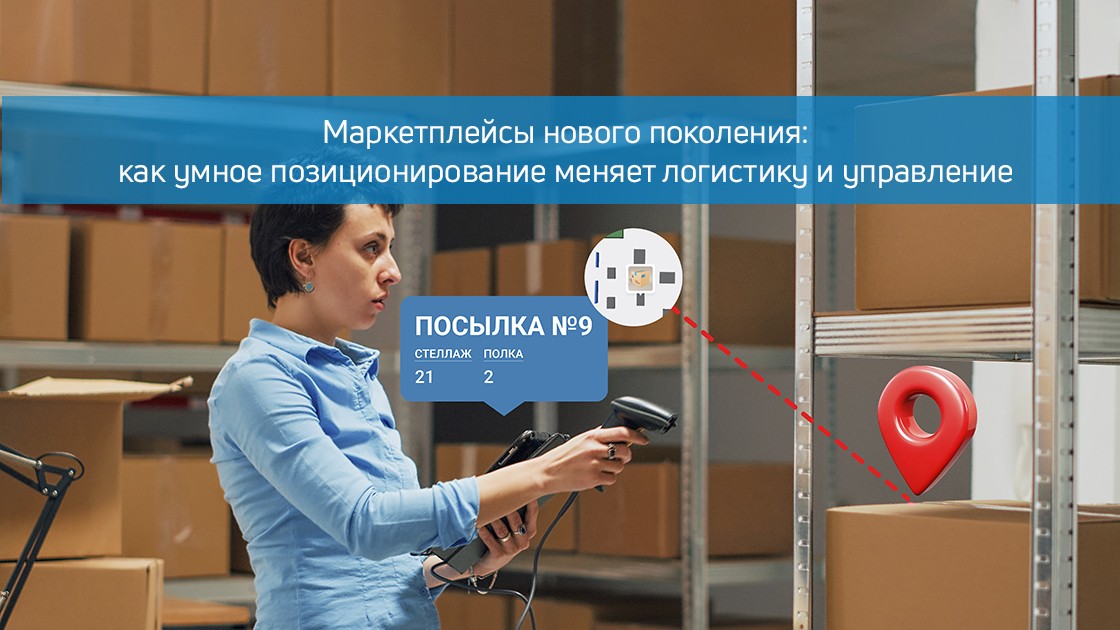

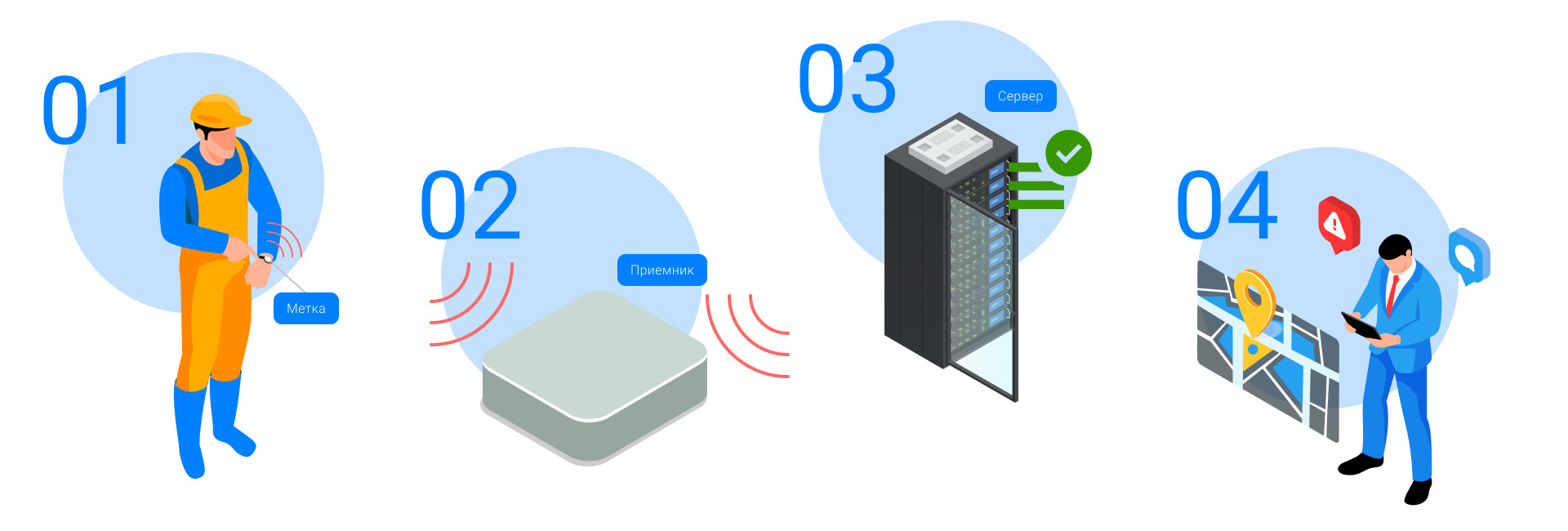

Современные EAM-решения всё чаще строятся на технологиях точного позиционирования и отслеживания объектов внутри помещений и на промышленных территориях. В основе таких систем лежит сбор данных о местоположении, перемещениях и состоянии активов в режиме реального времени.

Для этого используются специальные устройства — теги, маячки или метки, которые устанавливаются на оборудование, транспорт или инструменты. Они передают сигналы, которые принимаются считывателями, обрабатываются серверной частью и отображаются в удобном интерфейсе на компьютерах и мобильных устройствах пользователей. В зависимости от задач и условий применяются различные технологии позиционирования: Bluetooth® Low Energy (BLE), Wi-Fi, UWB и другие.

Indoors Navigation Platform объединяет эти технологии в единой цифровой среде, позволяя предприятиям получать точные данные о движении и использовании активов, а также интегрировать их с бизнес-процессами.

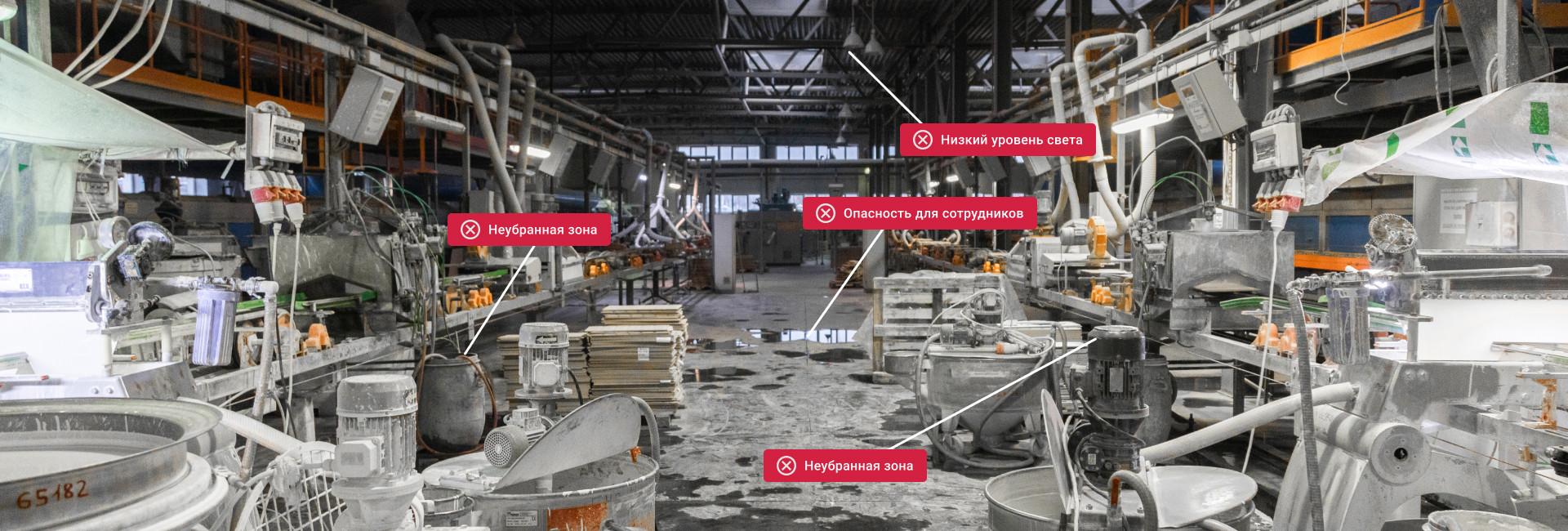

Почему предприятия сталкиваются с проблемами без EAM

Многие производственные компании до сих пор недооценивают важность системного управления активами. В результате руководители регулярно сталкиваются с типичными проблемами:

- несвоевременное техническое обслуживание оборудования;

- потери и хищения техники и инструментов;

- простои производства;

- рост аварийности и нарушение требований охраны труда.

Внедрение EAM-системы на базе трекинга позволяет значительно снизить вероятность подобных ситуаций и создать прозрачную, управляемую производственную среду.

Функциональные возможности системы управления активами

Платформы класса EAM, такие как Indoors Navigation Platform, решают сразу несколько ключевых задач:

- точное определение местоположения активов на территории предприятия;

- отслеживание маршрутов перемещения техники и оборудования;

- геозонирование и контроль доступа к отдельным зонам;

- создание цифровых карт цехов и корпусов с прокладкой оптимальных маршрутов;

- автоматические оповещения и уведомления при нештатных ситуациях;

- сбор аналитики по эксплуатации и загрузке активов.

Такие возможности делают систему универсальным инструментом для различных отраслей — от машиностроения и фармацевтики до пищевой промышленности и логистики.

Какие активы наиболее важно контролировать

С помощью программного обеспечения для управления активами предприятия могут отслеживать практически любое ценное имущество. Наиболее востребованные категории:

Транспорт и мобильная техника

Погрузчики, тележки, спецтехника, грузовые автомобили и другое передвижное оборудование.

Производственное оборудование

Станки, автоматизированные линии, генераторы, энергетические и вспомогательные установки.

Инструменты и приборы

Измерительное оборудование, лабораторные приборы, производственный инвентарь и оснастка.

- повысить уровень безопасности объекта;

- исключить человеческий фактор и формальный подход;

- обеспечить прозрачность и доказуемость выполнения обязанностей;

- сократить затраты на администрирование охранных служб;

- интегрировать контроль обходов с другими системами безопасности.

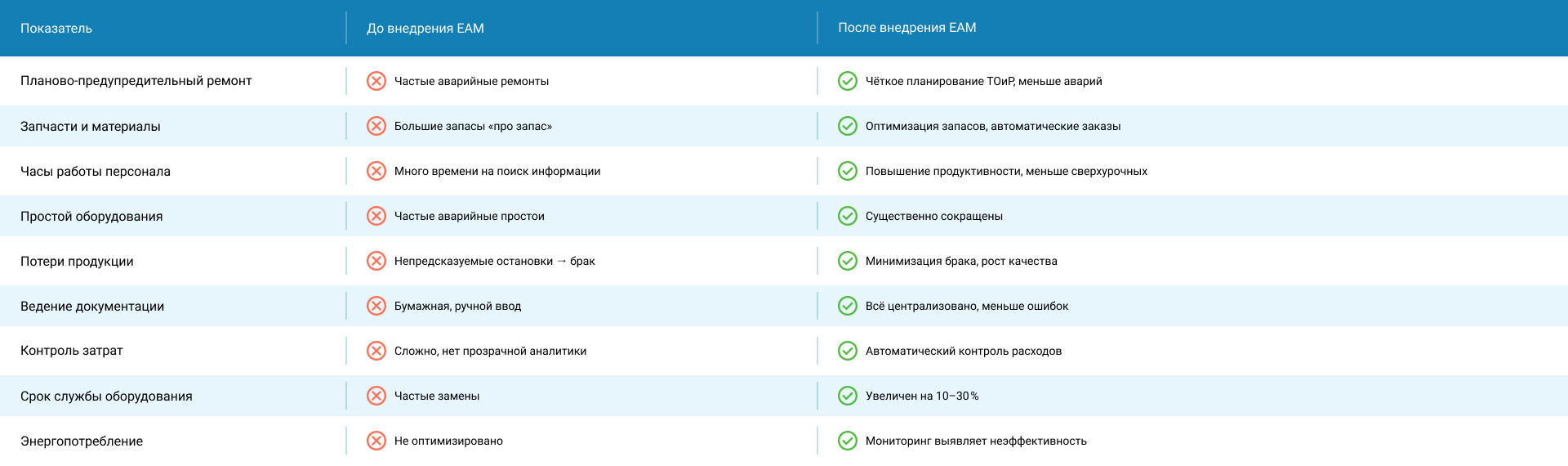

Основные преимущества EAM для промышленности

Рост операционной эффективности

Контроль состояния и загрузки активов позволяет выявлять узкие места в производственных процессах. В сочетании с аналитикой и прогнозированием это помогает минимизировать внеплановые простои, оптимизировать обслуживание и повысить общую производительность оборудования.

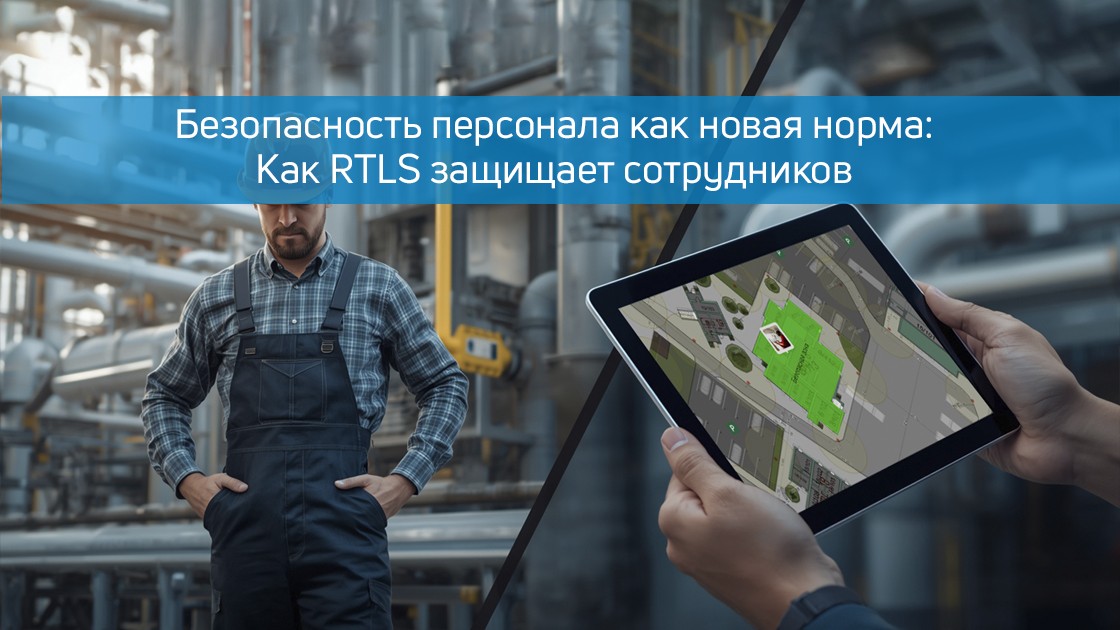

Повышение уровня безопасности

Работа в промышленности связана с повышенными рисками. Системы управления активами обеспечивают:

- снижение числа производственных инцидентов;

- повышение видимости техники и персонала;

- мгновенные оповещения о ЧП, опасных сближениях транспорта и людей.

Сокращение затрат и повышение ROI

EAM помогает выявлять неэффективно используемое оборудование, оптимизировать распределение ресурсов и внедрять профилактическое обслуживание. Это продлевает срок службы активов, снижает расходы на ремонт и повышает возврат инвестиций.

Гибкость и конкурентоспособность бизнеса

Данные, получаемые в реальном времени, позволяют руководству быстро принимать обоснованные управленческие решения. Компания становится более адаптивной к изменениям рынка и способной сохранять конкурентные позиции даже в условиях нестабильной экономики.

Улучшение качества продукции

Исправное и своевременно обслуживаемое оборудование напрямую влияет на стабильность качества выпускаемой продукции. Раннее выявление неисправностей снижает количество дефектов и повышает доверие клиентов.

Лучшие практики управления активами

Для достижения максимального эффекта предприятиям рекомендуется:

- использовать системы трекинга активов и планирования ТО для регулярного профилактического обслуживания;

- внедрять риск-ориентированный подход и соблюдать отраслевые нормативы;

- принимать управленческие решения на основе аналитических данных и KPI.

Indoors Navigation Platform поддерживает все эти сценарии, объединяя мониторинг, аналитику и визуализацию в единой экосистеме.

Будущее EAM: IoT и искусственный интеллект

Развитие Интернета вещей и искусственного интеллекта открывает новые горизонты для управления производственными активами. IoT-устройства позволяют собирать большие объёмы данных в режиме реального времени, а ИИ — анализировать их, прогнозировать отказы и оптимизировать обслуживание.

Преимущества таких решений включают:

- рост производительности;

- сокращение затрат на ремонт;

- уменьшение времени простоя;

- повышение качества продукции.

При этом важно учитывать вопросы кибербезопасности и подготовки персонала. Грамотный подход к внедрению технологий позволяет минимизировать риски и получить максимальную отдачу.

Conclusion

Системы управления активами сегодня являются неотъемлемой частью современной промышленности. Они помогают предприятиям эффективно контролировать оборудование, повышать безопасность, снижать затраты и увеличивать срок службы активов.

Использование платформы на базе трекинга, такой как Indoors Navigation Platform, позволяет вывести управление активами на новый уровень, обеспечить прозрачность процессов и создать устойчивую основу для роста бизнеса в долгосрочной перспективе.

Оставьте заявку на: https://indoorsnavi.pro/

👇 Subscribe and keep up to date with innovations! 👇