2023

Tracking employees at an industrial plant

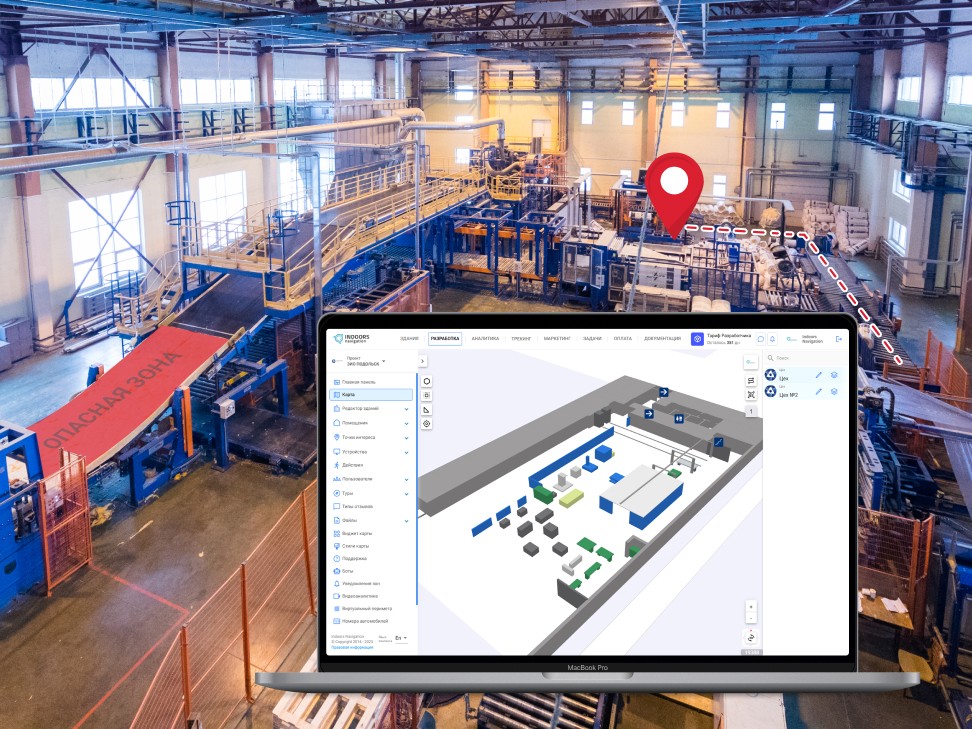

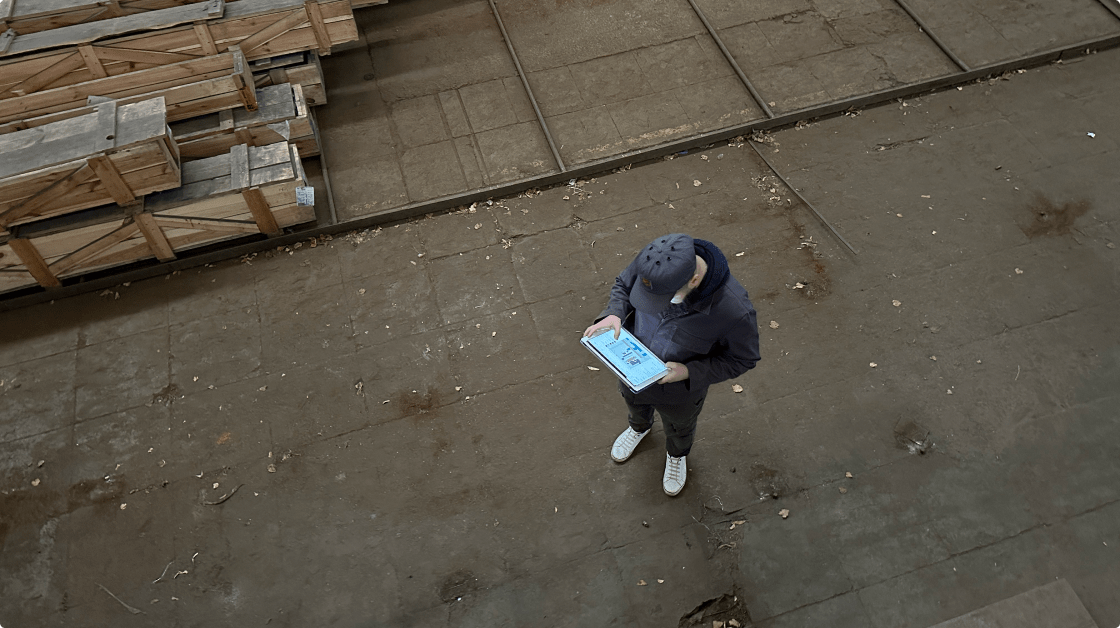

Indoors Navigation has implemented an employee tracking system in one of the workshops of the machine-building plant

The aim of the project was to ensure accurate monitoring of employee movements in the company's workshops to improve safety, control working hours and optimize internal processes. The project was implemented on the basis of the Indoors Navigation Platform (INF) using Ultra-Wideband (UWB) technology, which made it possible to achieve high positioning accuracy and low latency in real-time data display.

up to 10 cm

Positioning

accuracy

<1 sec

Data display

delay

by 15%

Risk reduction

System description and usage examples

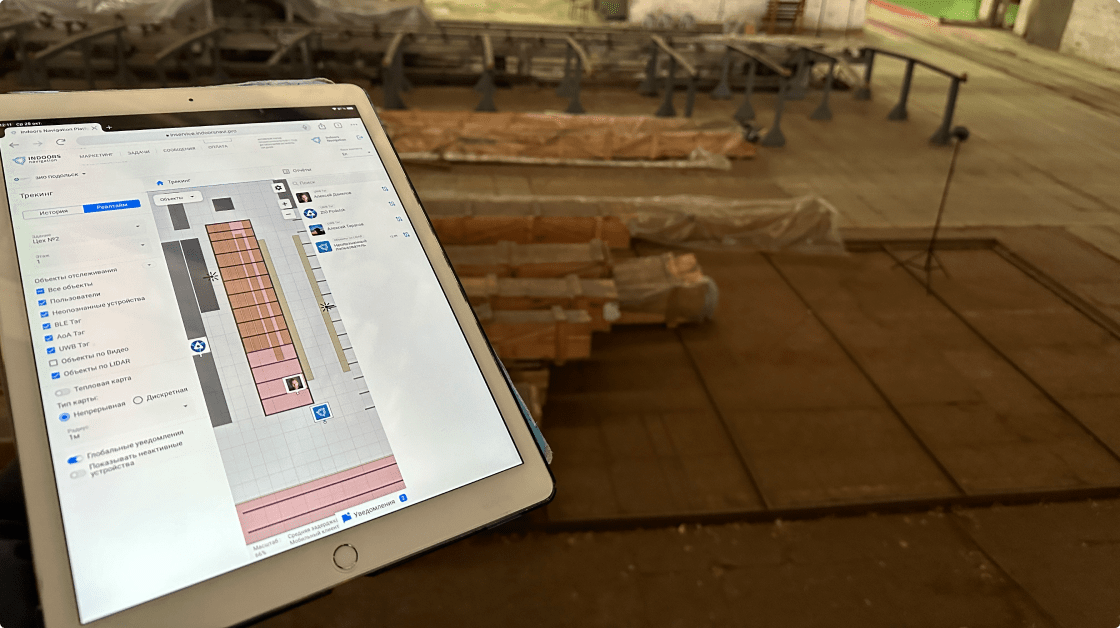

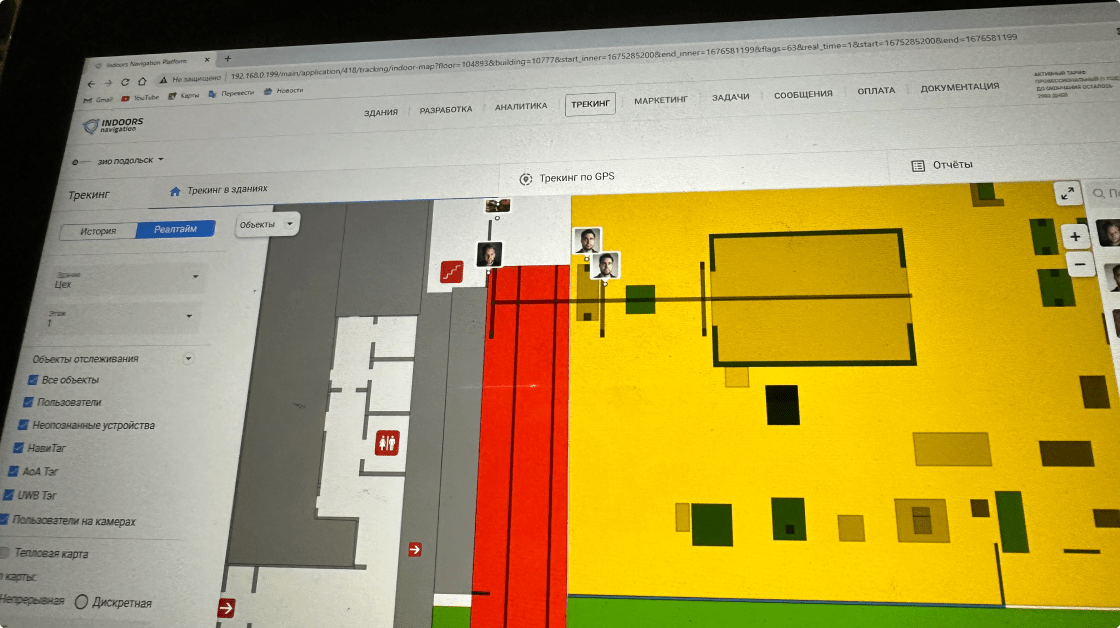

The INP tracking module was deployed on the territory of the enterprise using wearable tags integrated into personal protective equipment (PPE). UWB tags were embedded in employees' helmets and allowed them to track their location with an accuracy of 30 cm with a delay of less than one second.

The tags, provided with autonomous power for up to 14 days, transmitted information about the movement of employees to the central control panel, where administrators could track the location of employees in real time. In addition, the system was integrated with the warnings functionality: when an employee entered a dangerous area, a notification was automatically sent to the dispatcher and duplicated in the telegram bot.

Examples of using the system:

- Working Time Monitoring: Employee movement reports allow the administrator to analyze how much time an employee has spent at his workplace, which helps to increase discipline and identify inefficient areas.

- Occupational safety: If you enter a dangerous area, the system immediately sends a notification to the dispatcher, which allows you to take prompt measures to prevent accidents.

- Production flow tracking: The system helps to control the movement of employees between different areas of the enterprise, which improves the management of production processes.

Technical architecture

To implement the project, UWB receivers, laser scanners and IP video cameras were installed at the enterprise. These components ensure reliable coverage of all test areas, and the use of UWB technology guarantees accurate tag tracking even in conditions of high density of equipment and vehicles.

The main components of the system:

- UWB tags: Lightweight and compact, with a high degree of protection (IP66), integrated into employee helmets and badges.

- Server hardware: The central server processes the data coming from the tags and transmits the information to the control panel.

- Centralized Control Panel: Allows administrators to track movements in real time, analyze data, and configure the system for various scenarios.

Potential metrics

- Positioning accuracy: The system has achieved tracking accuracy of up to 30 cm when using UWB tags and 10 cm when using lasers.

- Data display delay: The delay time did not exceed 1 second, which makes the system operational and suitable for real-time monitoring.

- Risk reduction: Notifications about entering hazardous areas helped reduce the risk of industrial accidents by 15% during the first months of the system's operation.

Implementation results

The implementation of the Indoors Navigation Platform in production has demonstrated the high efficiency of the system in an industrial enterprise. The system allowed not only to improve control over the movements of employees and their safety, but also to optimize the work of production by more accurately tracking movements and working hours. In addition, integration with external systems through an open API has opened up additional opportunities for using movement data in various business processes.

Conclusion

Indoors Navigation Platforms has demonstrated its value as a tool for improving occupational safety and optimizing processes in manufacturing plants. The tracking system based on UWB tags provides accurate and prompt tracking of employee movements, which helps to significantly reduce risks and increase work efficiency.

Navigation in production

Automation of production has been a trend in recent years. The digital twin of factory and workshop navigation with motion monitoring is one of the important factors in increasing productivity and occupational safety.

UWB navigation, how does it work?

Ultra-broadband positioning (UWB positioning)— one of the latest technologies for determining indoor position. Navigation accuracy is up to 0.5 meters.

Thematic publications on our blog

Tracking employees in production using INP

Improving work efficiency by optimizing the working hours of employees and controlling their movement at a factory or other industrial facility is one of the most important tasks for any modern company considering…