Personnel tracking

Increasing the efficiency and safety of work by optimizing the working hours of employees and controlling their movement at the facility is one of the most important tasks for any company.

Online tracking of employees at the enterprise, accounting of working hours, control of restricted and dangerous zones, use of the INS, is possible in the geographic information system of the Indoors Navigation Platform.

A special mobile application is installed on the phone for employees (a badge or bracelet is issued), and electronic tags are attached to tangible assets.

The administrator monitors the movement of staff in real time, can control their places of stay and working hours, and see the movement of material assets inside the building and on the territory of the enterprise.

The GIS system based on the Indoors Navigation platform continuously monitors the movement of employees in the building and tangible assets, while maintaining the tracks of all routes.

Tracking the movement of personnel

Improving labor efficiency, as the company's management can at any time see where an employee is in real time. And with the help of the built-in messenger, quickly give instructions and distribute them to their places.

Control of the safety of tangible assets

The ability to track assets and equipment being moved will minimize losses, breakdowns and extend service life, thereby saving depreciation charges.

Control of dangerous and restricted areas

Improving occupational safety through automatic notification when an employee is in a dangerous area and notification of incidents at the enterprise. Improving industrial safety by informing employees when they enter someone else's work area or which they do not have access rights to.

Employee working time analysis

Recording of crowded areas during the working day and a heat map. Creating automatic reports on the time of arrival and departure from work, smoke breaks and lunch, and being in different areas of the enterprise.

Minimization of accidents at the enterprise

Due to the visualization of all movements and timely notifications, the possibility of collisions of equipment, hitting an employee and forgotten victims during evacuation is minimized.

Monitoring the use of SIZ and regulations

Automatic notification when an employee is present without using personal protective equipment. Prompt notification of employees about changes in the company, informing about incidents and timely organization of flows of people.

How is the employee movement control system useful?

Using spatial analysis tools, you can take a fresh look at your data. Tracking the location of employees will provide an opportunity to estimate the amount of time they spend at their workplace during the day and analyze where they go to work.

For example, in retail, you can use customer location tracking in a store and evaluate the timing of purchases of goods to a location in the retail area, as well as analyze the density distribution of potential customers relative to your point of sale.

Thematic publications on our blog

Positioning of employees of an industrial enterprise

Indoors Navigation conducted a test implementation of the employee positioning system at an industrial enterprise. On Premises the Indoor navigation Platform geographic information system solution has been deployed…

Application of positioning and tracking of construction workers

Modern construction sites are becoming more complex and large-scale. To manage these facilities effectively, developers and builders need to use advanced technologies. One of these techniques…

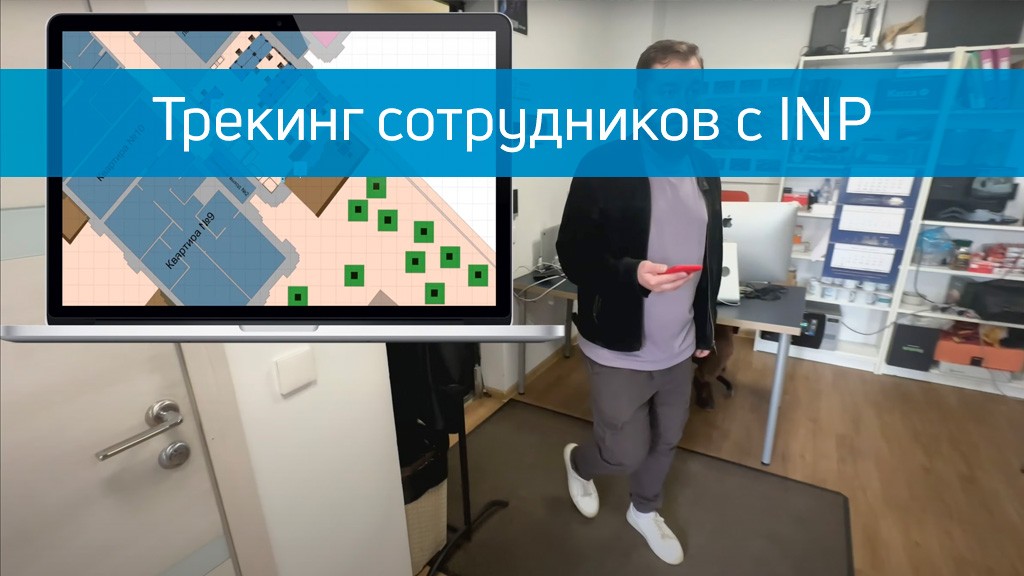

Employee tracking with INP

Testing the operation of the personnel tracking module in the Indoors Navigation Platform (INP) geographic information system simultaneously using BLE and UWB technology. During testing, staff movements are monitored using various technologies such as BLE positional sensors and Ultra-WideBand.…

A thematic case in our portfolio

Employee tracking

A system for monitoring the movement of employees in offices

Occupational safety at work

+20%

Industrial safety of the enterprise

+10%

Safety of equipment and machinery

+22%

Frequently Asked questions about employee tracking

What is personnel tracking in production and why is it necessary?

Tracking personnel in production helps to optimize processes and increase employee safety. Tracking allows you to monitor staff movements and equipment usage, as well as obtain data for performance analysis and resource management.

How does the personnel tracking system work in production?

The production personnel tracking system uses various technologies such as UWB, AoA, Bluetooth, Wi-Fi, GPS, RFID,to determine the location of personnel and equipment. Data is collected and processed to optimize processes and increase security.

What are the advantages of using a personnel tracking system in production?

Using a personnel tracking system in production makes it possible to increase safety, reduce the time needed to find the necessary materials and equipment, optimize production processes, manage resources, and obtain data for analysis and decision-making.

What technologies are used for personnel tracking in production?

Various technologies such as UWB tags, Bluetooth wristbands, Wi-Fi, GPS and others are used for tracking personnel in production. The choice of technology depends on the specifics of production and the tasks that need to be solved. As well as tracking accuracy.

What data is collected by the personnel tracking system in production?

The production personnel tracking system collects data on personnel movements, equipment and material usage, working hours, and other data that can be useful for analyzing work efficiency and resource management.

What are the possibilities for analyzing the data collected by the personnel tracking system?

The personnel tracking system can collect various data, such as location, time spent in the zone, speed of movement, etc. This data can be used to analyze and optimize production processes. The following are the possibilities for analyzing the data collected by the personnel tracking system:

- Production process efficiency analysis: Data on personnel movement across production areas can be used to analyze the effectiveness of production processes. The analysis allows you to identify areas where there are delays and identify the causes of these delays, which improves productivity and reduces production time.

- Optimization of logistics processes: A personnel tracking system can help optimize logistics processes by providing information about the movement of personnel and equipment in production. Analyzing this data can improve route planning, optimize material delivery costs, and improve inventory management.

- Safety analysis at work: The data collected by the personnel tracking system can be used for safety analysis at work. For example, if the system detects an intersection of a certain safety zone, you can immediately receive a message about a violation of safety regulations at work.

- Employee Productivity Assessment: A personnel tracking system can help evaluate the productivity of each employee in production. Analyzing data on movement and time spent in an area can help identify the personnel working most efficiently, as well as identify areas where productivity can be improved.

- Monitoring the general condition of the equipment: The data collected by the personnel tracking system can be used to monitor the general condition of the equipment. The analysis of this data can make it possible to predict equipment failures and plan preventive measures.

How does the personnel tracking system help improve safety at work?

Tracking personnel in production helps to increase the safety of employees and prevent possible dangerous situations. The tracking system allows you to receive data on the location of employees in real time, which allows you to monitor their movement in production and prevent dangerous situations associated with crossing prohibited areas or possible collisions with other employees or equipment.

In addition, the tracking system allows you to quickly locate an employee in the event of an emergency, which can save an employee's life. Also, the analysis of personnel movement data makes it possible to identify potential threats and optimize safety at work, which can lead to a reduction in the number of industrial accidents and an increase in the efficiency of the enterprise.

What are the possibilities for integrating the indoor personnel tracking system with other control systems in production?

The indoor personnel tracking system can be integrated with various production management systems, which allows for improved management and control of production processes. Here are some examples of possible integrations:

- Integration with access control systems: using the personnel tracking system, it is possible to monitor employee access to various areas of the production facility in real time, which increases security and prevents unauthorized access.

- Integration with equipment management systems: The tracking system can be integrated with production equipment management systems such as conveyors, cranes, and robots. This allows you to automatically control the movement of employees and equipment, which increases the safety and efficiency of production processes.

- Integration with energy management systems: The personnel tracking system can be integrated with energy management systems in production, which allows you to control energy consumption and optimize equipment operation based on employee movement data.

- Integration with production process management systems: The personnel tracking system can be integrated with production process management systems such as warehouse and inventory management systems, which optimizes management processes and increases production efficiency.

In general, the integration of the personnel tracking system with other production management systems makes it possible to create a single management center that improves the management and control of production processes and increases safety at the enterprise.

How can an indoor navigation system help with logistics and inventory management in production?

An indoor navigation system can help with logistics and inventory management in production by providing real-time information about the movement of goods and employees inside the building.

Here are some examples of how an indoor navigation system can help with logistics and inventory management in production.:

- Cargo route optimization: An indoor navigation system can help optimize cargo routes in production, which reduces cargo delivery time and reduces transportation costs.

- Improve inventory accuracy: Using the indoor navigation system, you can track the movement of goods and inventory items in real time, which improves inventory accuracy and reduces the likelihood of errors.

- Inventory Optimization: An indoor navigation system can help optimize inventory levels in production based on sales and product movement data.

- Improving Warehouse accounting efficiency: An indoor navigation system can help improve warehouse accounting by automatically tracking the movement of goods in and out of the warehouse.

- Improve production process management: An indoor navigation system can help improve production process management by providing real-time information about the movement of goods and employees inside the building.

Overall, an indoor navigation system can help optimize logistics and inventory management in production, increasing efficiency and reducing costs.

How can a personnel and equipment monitoring system help reduce the time needed to find the necessary equipment and materials in production?

A personnel and equipment monitoring system can help reduce the time spent searching for necessary equipment and materials in production by providing real-time information about the location of equipment and materials.

Here are some examples of how a personnel and equipment monitoring system can help reduce the time needed to find the necessary equipment and materials in production.:

- Quick equipment search: The personnel and equipment monitoring system can help you quickly find the right equipment in production by displaying its location on the building map or on the control board.

- Inventory Management: A personnel and equipment monitoring system can help manage inventory by providing information about how many materials are available in production, where they are located, and when they need to be ordered.

- Quick access to tools and equipment: A personnel and equipment monitoring system can help reduce the time spent searching for necessary tools and equipment by providing information about their location and availability.

- Optimizing repair and maintenance processes: A personnel and equipment monitoring system can help optimize equipment repair and maintenance processes by providing information about its technical condition and location.

- Improving production process management: A personnel and equipment monitoring system can help improve production process management by providing real-time information about the location of equipment and materials.

In general, a personnel and equipment monitoring system can help reduce the time needed to find the necessary equipment and materials in production, increase the efficiency of production processes and reduce costs.