Navigation on the building

Using navigation systems on a construction site can be very useful for improving productivity and safety on the construction site. Navigation systems enable efficient resource management, optimize processes, and reduce construction costs.

The geographic information system (GIS) of the Interiors Navigation Platform (INP) is used to ensure safety at the construction site and includes access control to hazardous areas, monitoring of workers' actions and movement of equipment.

Using navigation on a construction site can help improve the efficiency of construction work, reduce costs, and improve safety by making the construction process more transparent and competitive.

Digitalization of the construction site helps to speed up ongoing processes, improve quality and safety, and reduce construction costs.

Digitalization of construction means the use of new technologies and tools to improve construction processes. This includes using digital technologies to manage projects, improve safety, improve work quality, and reduce construction time.

BIM modeling: The use of 3D models helps to speed up design and construction, as well as reduce errors. BIM models can be used for planning, resource management, quality control, and risk assessment.

IoT technologies: Embedded sensors and IoT devices can be used to monitor the condition of equipment, control the flow of materials, and control temperature and humidity at a construction site.

Data analytics: Data collection and analysis allows you to optimize construction and resource management processes, as well as identify problems and risks.

Advantages of implementing positioning on the construction site:

Improved security:

Positioning systems can be used to track the movement of people and equipment on a construction site, which can help prevent emergencies and ensure the safety of workers by controlling access to hazardous areas and monitoring their actions in detail.

Improving efficiency:

Thanks to the geographic information system, it is possible to locate all resources on the construction site and manage them more efficiently. This allows you to reduce the time of work and reduce costs.

Online resource management:

Navigation systems can be used to manage resources on a construction site, such as building materials, equipment, and labor. This will reduce construction costs and increase resource efficiency, as well as improve planning, forecasting and control of the construction process.

Improved quality control:

Positioning systems can be used to monitor the quality of work on a construction site, which can help identify and eliminate deficiencies and errors at an early stage, compare actual results with design results, and quickly identify deviations.

Improved interaction with workers:

Positioning systems can help establish more effective communication and interaction between the various project participants, which will contribute to a more successful construction implementation.

Navigation for construction vehicles:

GPS navigation can be used to control the movement and operation of construction machinery on the site. This helps to reduce errors and repetitive work, as well as improve productivity.

Navigation for logistics:

Navigation systems can be used to optimize logistics at a construction site, for example, to determine the optimal route for the delivery of materials and equipment.

Caring for employees

Taking care of construction workers is one of the most important aspects in the construction industry.

The use of modern positioning and tracking systems at the construction site improves the working conditions and safety of workers. For example, worker movement tracking systems automatically monitor workers' access to dangerous areas of the construction site, ensure safe movement at height, and determine the location of each worker.

This helps to reduce the number of accidents on the construction site and increases work efficiency, as workers can find the right construction sites, the location of equipment and tools faster and more accurately.

What the builder gets:

- Improved security. Positioning systems can help control access to dangerous areas of a construction site, ensure safe movement in height, and determine the location of each worker on the site. This can reduce the number of accidents at the construction site and improve the safety of workers.

- Improvement of working conditions. Positioning systems can help workers find the right construction sites and equipment locations faster and more accurately. This can improve work efficiency and reduce worker fatigue.

- Improved communication. Positioning systems can provide better communication between workers and project managers, as everyone will be able to know where other construction participants are located.

- Increased productivity. Positioning systems can help improve resource management, optimize processes, and reduce costs. This can lead to increased productivity and higher wages for workers.

Digitalization of the store

Digitalization of construction using modern navigation makes it possible to increase work efficiency, reduce production costs and shorten construction time.

Positioning and movement tracking technologies help improve construction planning and management, increase worker safety, and provide more precise control over the construction process. In addition, the digitalization of construction helps to reduce the environmental impact and improve the quality of work performed.

What the developer gets:

- Increasing the efficiency of construction management. Online monitoring of the progress of work, control costs and reduce the likelihood of errors.

- Improved planning and coordination of work: With the help of data obtained from the positioning and motion tracking system, the developer can improve the planning and coordination of work on the construction site, which will lead to improved productivity and shorter project execution time.

- Improved security: The geographic information system will help in managing safety at the construction site, for example, by warning workers about high-risk areas or detecting unusual movement on the construction site, which may indicate safety problems.

- Reducing errors and flaws: By providing more accurate information about the location of workers and equipment at the construction site, the developer can reduce the number of errors and deficiencies, which can lead to lower costs for correcting these problems.

- Improved transparency: The developer can use the positioning and movement tracking system to obtain more complete information about the work on the construction site and provide it to interested parties such as investors or regulators, which can improve transparency and increase confidence in the project.

- Increased resource efficiency: The developer can use the information obtained from the positioning and motion tracking system to optimize the use of resources such as equipment, materials, and labor, which can lead to cost reductions and increased profits.

Relevance

The use of modern positioning and monitoring technologies will enhance safety and improve work processes, increasing worker satisfaction.

Thematic publications on our blog

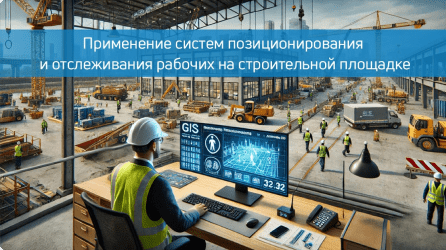

Application of positioning and tracking of construction workers

Modern construction sites are becoming more complex and large-scale. To manage these facilities effectively, developers and builders need to use advanced technologies. One of those…

Low-power global network: choosing the best positioning option

The Low-Power Global Network (LPWAN) first emerged as a result of the need to reduce the size and cost of IoT devices while maintaining battery efficiency. Providing long-range communication with low energy…

How digital maps help developers sell real estate.

In today's digital world, successful real estate sales require an innovative approach. Digital maps of objects, such as those offered by Indoor Navigation, are becoming an integral part of the strategy.…

Intercom — from hearing aids to IoT

The world has changed a lot since the first intercom was invented more than 100 years ago. At that time, residents of apartment buildings bought goods at the market within walking distance from their homes, traveled only on special occasions and rarely worried about an unexpected guest visiting them. Today they buy in…

Frequently asked questions about navigation on the construction site

Why is GIS needed on a construction site and what tasks does it solve?

GIS at a construction site allows you to effectively manage the territory, track resources, monitor the movement of equipment and personnel, and monitor the progress of construction in real time. This simplifies coordination and improves compliance with deadlines and budgets.

What advantages does GIS bring specifically for construction processes?

OGIS helps optimize the allocation of equipment and resources, minimize risks on the construction site, and ensure accurate documentation of construction progress, which is important for reporting and decision-making.

How does GIS help improve safety at a construction site?

The system can monitor access to dangerous areas, track the location of personnel and equipment, and detect potentially dangerous situations, which reduces the risk of injury and incidents.

Can GIS data be used for reporting and monitoring?

Yes, the system allows you to automate the collection of information for reporting, including documenting construction stages, which helps to track project performance and demonstrate progress to investors.

Can GIS be used to track equipment and materials?

Yes, GIS allows you to track the movement and location of machinery and materials, ensuring control over resources and preventing theft or loss on the construction site.

How can GIS improve the accuracy of construction tasks?

The system allows you to track the exact position of equipment and personnel, helps with alignment, excavation planning and other tasks where high accuracy is required, which reduces the likelihood of errors.

How difficult is it to implement GIS on a construction site and what stages does the process include?

The implementation includes the installation of sensors and GPS trackers, software configuration and staff training. The complexity depends on the scale of the project, but the process usually takes from a few weeks to a month.

What are the other prospects for GIS development at the construction site?

In the future, GIS at the construction site can use the data for predictive analytics, predict possible delays, monitor equipment wear and improve interaction with other smart systems on the site.